This is a simple membrane reactor model described in a textbook.

H. Scott Fogler (2010), Section 6.4 Membrane Reactors,

Essentials of Chemical Reaction Engineering, p.p. 217-225

In the textbook, specific components were not specified.

So, I treated the reaction as propane dehydrogenation.

i.e. C3H8 (Propane) -> C3H6 (Propylene) + H2

In this example, heat duty was also calculated.

ACM is very convenient for user to consider the heat balance.

Because molar enthalpy can be taken with a single line as below.

Call (hret) = pEnth_Mol_Vap(T, P, zret) ;

Download ACM file (V8.8)

Download MSI file (V8.8)

Download Aspen Plus file (V8.8)

Model MembReactor

Kc As RealVariable

(Description:"Equilibrium constant [mol/dm3]", Fixed, 0.05);

k As RealVariable

(Description:"Reaction rate constant [1/min]", Fixed, 0.7);

Cto As RealVariable

(Description:"Total molar concentration [mol/dm3]");

kc_ As RealVariable

(Description:"Transport coefficient [1/min]" , Fixed, 0.2);

V As LengthDomain (DiscretizationMethod:"OCFE4",

HighestOrderDerivative:1,

Length:500,

NumSections:2,

SpacingPreference:5,

Section(2).Location:100,

Section(2).SpacingPreference:20);

Fa As Distribution1D(XDomain Is V, HighestOrderXDerivative:1)

Of RealVariable(0); // [mol/min]

Fb As Distribution1D(XDomain Is V, HighestOrderXDerivative:1)

Of RealVariable(0); // [mol/min]

Fc As Distribution1D(XDomain Is V, HighestOrderXDerivative:1)

Of RealVariable(0); // [mol/min]

Nodes As IntegerSet([0 + V.Interior + V.EndNode]);

Ft(Nodes) As RealVariable; // [mol/min]

ra(Nodes) As RealVariable;

T As temperature;

P As pressure;

Q As enthflow;

// Inlet variables

Fin As RealVariable; // [mol/min]

zin(Componentlist) As molefraction;

hin As enth_mol;

Vin As vol_mol;

MWin As molweight;

// Retentate variables

Fret As RealVariable; // [mol/min]

zret(Componentlist) As molefraction;

hret As enth_mol;

rhoVret As dens_mol;

Vret As vol_mol;

MWret As molweight;

// Permeate variables

Fper As RealVariable; // [mol/min]

zper(Componentlist) As molefraction;

hper As enth_mol;

rhoVper As dens_mol;

Vper As vol_mol;

MWper As molweight;

// Ports

PortIn As Input MaterialPort;

PortRet As Output MaterialPort;

PortPer As Output MaterialPort;

// Inlet condition

PortIn.F = Fin / 1000 * 60 ;

PortIn.T = T ;

PortIn.P = P ;

PortIn.z = zin ;

PortIn.h = hin ;

PortIn.V = Vin ;

Cto = 1 / Vin ;

// Boundary condition (Inlet)

Fa(0) = Fin * zin("A") ;

Fb(0) = Fin * zin("B") ;

Fc(0) = Fin * zin("C") ;

// Component mole balances

For i In [V.Interior + V.EndNode] Do

Fa(i).ddx = -ra(i) ;

Fb(i).ddx = ra(i) - kc_ * Cto * (Fb(i)/Ft(i)) ;

Fc(i).ddx = ra(i) ;

EndFor

// Total molar flow

Ft = Fa + Fb + Fc ;

// Reaction rate

ra = k * Cto * ((Fa/Ft) - Cto/Kc * (Fb/Ft) * (Fc/Ft)) ;

// Average molar weight

Call (MWin) = pMolWeight(zin) ;

Call (MWret) = pMolWeight(zret) ;

Call (MWper) = pMolWeight(zper) ;

// Specific Vapor Molar Enthalpy

Call (hret) = pEnth_Mol_Vap(T, P, zret) ;

Call (hper) = pEnth_Mol_Vap(T, P, zper) ;

// Specific Vapor Molar Density

Call (rhoVret) = pDens_Mol_Vap(T, P, zret) ;

Call (rhoVper) = pDens_Mol_Vap(T, P, zper) ;

// Mass Balance

Fin * MWin = Fret * MWret + Fper * MWper ;

// Heat Balance

Fin * hin + Q * 1000 / 60 = Fret * hret + Fper * hper ;

// Retentate condition

Fret = Ft(V.EndNode) ;

zret("A") = Fa(V.EndNode)/Ft(V.EndNode) ;

zret("B") = Fb(V.EndNode)/Ft(V.EndNode) ;

zret("C") = Fc(V.EndNode)/Ft(V.EndNode) ;

Vret = 1 / rhoVret ;

PortRet.F = Fret / 1000 * 60 ;

PortRet.T = T ;

PortRet.P = P ;

PortRet.z = zret ;

PortRet.h = hret ;

PortRet.V = Vret ;

PortRet.Av= 1 ;

// Permeate condition

zper("A") = 0 ;

zper("B") = 1 ;

zper("C") = 0 ;

Vper = 1 / rhoVper ;

PortPer.F = Fper / 1000 * 60 ;

PortPer.T = T ;

PortPer.P = P ;

PortPer.z = zper ;

PortPer.h = hper ;

PortPer.V = Vper ;

PortPer.Av= 1 ;

End

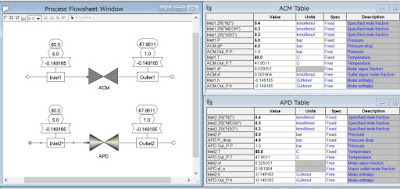

Example 6-2 Results (textbook)

Same results were obtained using ACM.

Heat duty was validated using Aspen Plus.